Building information modelling (BIM) is increasingly important across the construction sector.

We talked to MiTek Director of Plan Services, Ben Tabolt to find out why, and discover the important role Dedicated Services can play in helping South African companies benefit from digital design and build…

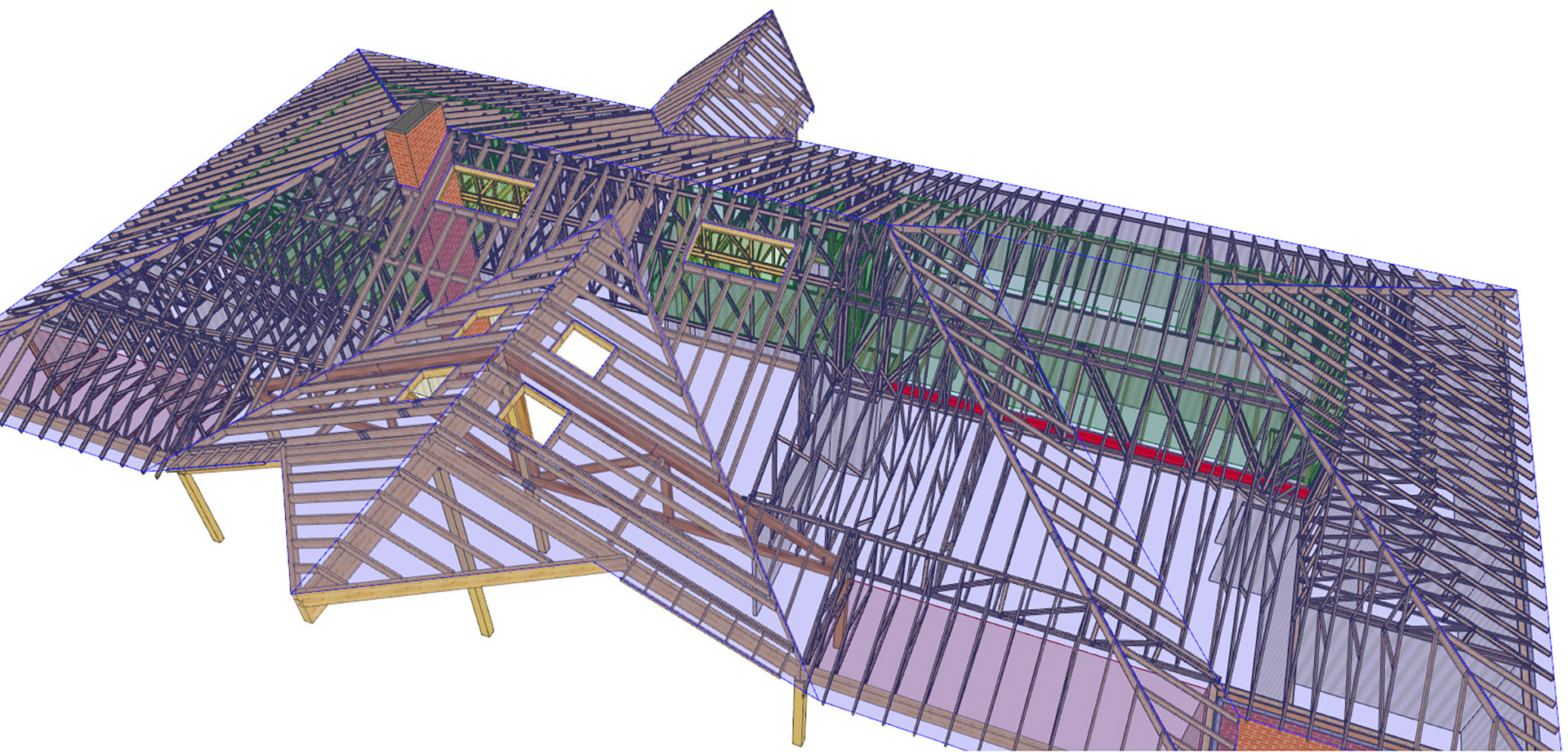

With a degree in architecture and many years of experience in design and construction across both the residential and commercial sectors, Ben is well placed to understand the critical importance of BIM. It can, he says, be a great tool for streamlining the design and construction process, giving the opportunity to ‘build it before you build it, so to speak’.

“Catching issues in the computer, not in the field once you’ve started physical work on the project is vital, but not everyone has the in-house expertise to support this effectively,” he says. And that’s where Dedicated Services comes into its own.

“Our team of experts brings together architectural degree experience with expertise in a host of software programs, which can be used to create BIM, with everything from estimating and drafting through to complex design, fabrication drawings and 3D modelling, including stills rendering and fly-throughs. It’s accessible to all companies whatever their size.”

Adds Ben: “We have a large estimating department that can assist with the material takeoffs, bill of materials, etc, even down to sticks of lumber. We can provide support whether it’s builders who need new product or maintenance of their plans; fabricators or component manufacturers that want assistance and maybe more muscle.

“We provide a very efficient solution by having a workforce at their disposal!”

MiTek’s Dedicated Services’ design solutions are delivered with offsite construction in mind – a more cost-effective, faster and ‘greener’ approach for any project whether residential or commercial, as Ben explained. “Because of the BIM that’s carried out by our Dedicated Services team, we can iron out potential issues, incorporate design changes and visualize projects for clients before any on-site work begins.

“It’s about optimization, collaboration and communication – meaning that when clients begin their building work, they have everything that’s needed, all to the correct specification, with minimal on-site changes required.”

The team can also help clients identify the best products to use with their designs – whether timber frames, Posi-joist or Ultra Span. “It means we’re presenting clients with an informed solution.”

Offsite fabrication, says Ben, means construction of client orders can take place in a controlled environment that’s not impacted by changes in weather conditions and means modular and panel solutions, and advance components, can be preassembled and then installed in the field once the construction team is ready.

“There’s less waste, components are built and made to measure, and mean safe, efficient and speedy installation can be achieved. And of course, this is a more financially economic approach.”

While Ben admits that off-site construction has yet to take off at scale in South Africa, he’s convinced that as innovation in the sector continues to grow, along with education of customers so they can see the benefits, this is set to change.

He adds: “We have our four pillars at MiTek- services, automation, software, and products – but while these are vital, it’s not enough just to have those types of solutions, it’s also about partnership for us. We want to collaborate with our clients and take that journey with them.

“We want to be effective advocates for both off-site and on-site construction and of course, for BIM, leading the charge into innovative design, make, build services, so we can give our clients absolutely the best, from conception through to building hand-over.”